Living by the water is a dream for many. The serene views, fresh air, and calming sound of waves or running water are just a few of the drawcards of waterside living. However, this idyllic lifestyle comes with its own unique set of challenges, especially when it comes to patio construction.

Building near water often means dealing with harsh environmental conditions that can take a toll on structures. Salt spray, high humidity, potential flooding and severe weather can significantly impact the longevity and durability of steel structures, posing a real challenge for homeowners and builders alike.

Some of the key challenges include:

High humidity and salt spray: Coastal environments have high humidity levels, and the salt content in the air speeds up corrosion. Salt spray results in salt deposits on building materials, which can lead to more rapid deterioration. This is a particular concern near the ocean but can also affect structures near large bodies of water due to the moisture-laden air.

Unwashed areas: Rainwater naturally washes away salt deposits from surfaces. However, structures like patios and carports have large unwashed areas where rainwater doesn’t reach, such as the underside of insulated panels. Salt can accumulate and accelerate corrosion in these areas.

Weather extremes: Coastal and waterside areas often experience high winds and storm surges, which can damage structures not designed to withstand such forces. More frequent and severe weather events can compromise building materials and exacerbate the effects of corrosion.

Proximity to pools: Even being near pools poses challenges due to the chlorine and other chemicals used in pool maintenance. These chemicals can also contribute to the corrosion of nearby structures.

To ensure longevity and durability of structures built in coastal and waterside homes, it’s essential to select materials and design strategies that can withstand harsh environmental conditions.

At Apollo Patios, we prefer UniCote® Coastal because it stands out as a product specifically engineered to address the unique challenges posed by coastal and waterside environments. A pre-painted steel product designed with advanced anti-corrosive properties, UniCote® Coastal is highly resistant to the damaging effects of salt spray, humidity, and extreme weather conditions.

Why UniCote® Coastal is the best choice for coastal areas

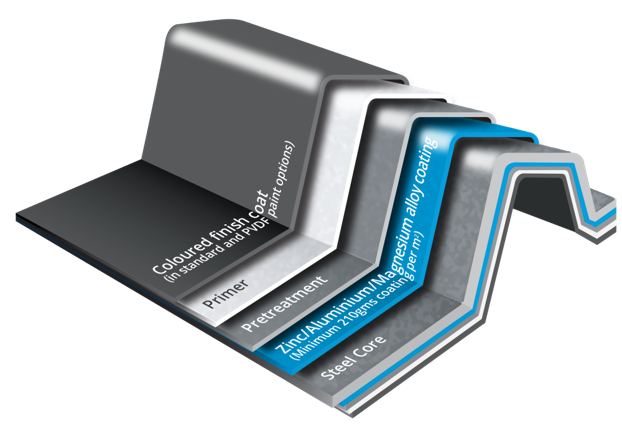

Superior corrosion resistance: UniCote® Coastal features an enhanced metallic coating system that provides excellent resistance to corrosion. The specially formulated coating significantly reduces the rate of degradation caused by salt-laden air, ensuring the longevity of the panels.

Advanced paint technology: The product uses advanced paint technology that includes a primer and topcoat designed to withstand the harsh coastal environment. This multi-layer paint system offers an additional barrier against corrosion, UV rays and physical wear, making it ideal for waterside areas.

Durability in unwashed areas: The coating on UniCote® Coastal is particularly effective in unwashed areas, where traditional materials may fail. Its robust coating ensures that even in areas not regularly washed by rain, such as the undersides of panels, the material remains protected from salt buildup and corrosion.

High weather resistance: UniCote® Coastal is designed to endure extreme weather conditions. Its strong adherence to the substrate prevents peeling and chipping, even in high wind and storm-prone areas. This ensures the structural integrity of buildings during severe weather events.

Aesthetic longevity: Beyond functional durability, UniCote® Coastal maintains its aesthetic appeal over time. The high-quality finish provides excellent colour fastness, ensuring that buildings retain their vibrant appearance despite any potentially harsh waterside environment.

Sustainability: UniCote® Coastal is environmentally friendly, manufactured using processes that minimise environmental impact. Its longevity and durability mean fewer replacements and repairs, contributing to sustainable building practices.

Enhanced coating: The metallic coating is 30% thicker, providing superior protection in harsh waterside environments. This thicker coating acts as an additional shield against the corrosive effects of salt spray, high humidity and chlorine from pools, significantly reducing the likelihood of rust and deterioration.

Warranty coverage: UniCote® offers site-specific warranties of varying durations for UniCote® Coastal depending on the environment and distance from water. Simply email the address of the project and Apollo will confirm the warranty you’ll receive with UniCote®. The UniCote® warranty also covers unwashed areas and the ceiling of insulated panel.

Maintenance plan: UniCote® Coastal comes with a comprehensive maintenance plan designed to ensure your insulated panels last for many years, even in the most challenging waterside conditions. This proactive approach not only extends the lifespan of the panels but also reduces long-term maintenance costs and enhances overall building performance.

Choosing the right materials is crucial to ensuring the longevity and durability of structures in waterside areas. UniCote® Coastal provides a robust solution with its superior corrosion resistance, advanced paint technology, and high weather resilience. By selecting UniCote® Coastal, you can enjoy the serene waterside lifestyle without compromising on the structural integrity and aesthetic appeal of your building.

Apollo offering in UniCote® Coastal Steel

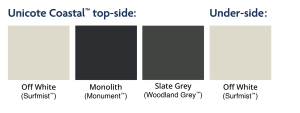

Insulated Panel Roofing Colours

Single Skin Steel Roofing – Apollo Outdoor Flat MKII Colours

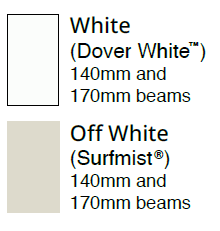

Apollo Beam Colours and Sizes in Unicote® Coastal Steel

Click here to learn more about Unicote® Coastal Steel